1 月 . 20, 2025 00:05 Back to list

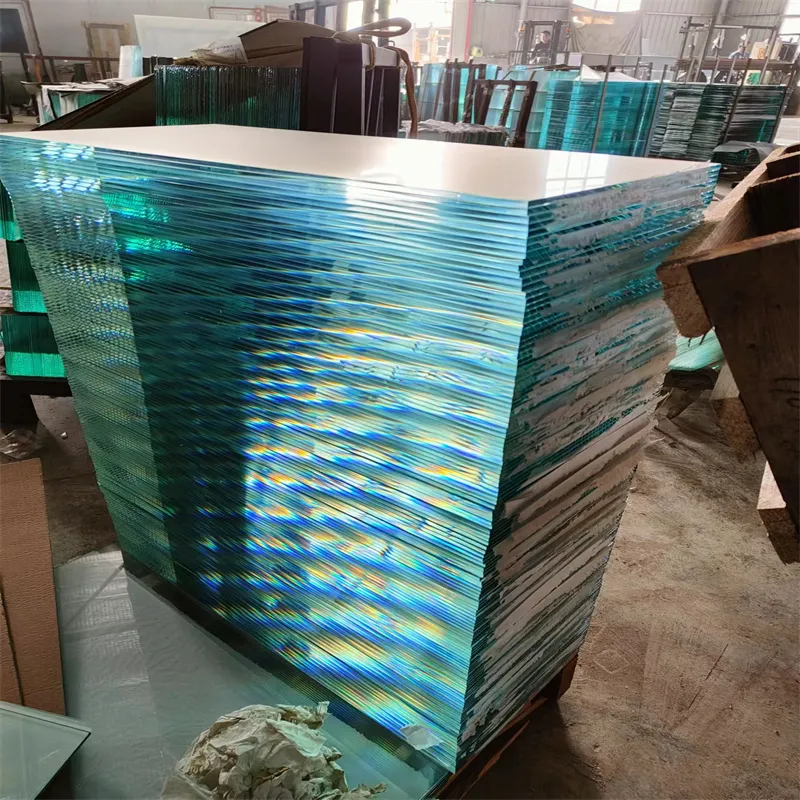

types of glass coating

Glass coatings have emerged as a significant advancement in the realm of materials science, offering improved durability, aesthetics, and functionality to various products. Understanding the diverse types of glass coatings is essential for industries ranging from automotive to architecture that rely on these protective and enhancement solutions. This detailed overview explores the primary categories of glass coatings, emphasizing their unique properties and applications, backed by expert insights and authentic experiences.

4. Anti-Glare Coatings Reducing glare is essential in environments with prevalent digital screens and excessive lighting. Anti-glare coatings diffuse light rather than only reducing reflections, proving indispensable in enhancing display quality for computers, televisions, and other devices. Drawing from extensive experience, the application of matte finishes and microscopic surface adjustments enhances screen readability and reduces strain, showcasing not just technical expertise but also a commitment to user experience. The trusted effectiveness of such coatings in improving screen usability underscores their pervasive utilization. 5. Scratch-Resistant Coatings Scratch-resistant coatings are crucial in extending the lifespan of glass products, offering protection against wear and tear. In sectors like automotive, consumer electronics, and eyewear, these coatings protect glass from both minor abrasions and significant scratches. The challenge and expertise lie in developing hard yet transparent layers, often employing nanotechnology materials such as nano-diamonds or advanced silica composites. Trustworthiness in this realm is demonstrated by rigorous testing and certification standards that validate the impressive durability these coatings provide. 6. UV-Resistant Coatings Protecting glass from ultraviolet radiation is critical in preserving both the material itself and the interiors it shields. UV-resistant coatings prevent harmful rays from penetrating through glass, an important feature in automotive windows and architectural elements. The effectiveness of these coatings, developed with precision and expertise, is validated by their widespread use in minimizing UV exposure damage. This reliability resonates with consumers and industries seeking authoritative protection against UV degradation. It is evident that glass coatings are not mere ornamental enhancements but are integral to improving functionality and longevity across multiple sectors. Their development, characterized by authentic expertise and a deep understanding of materials science, promotes energy efficiency, aesthetic appeal, and protection. In choosing the appropriate type of glass coating, industries rely on the authoritative knowledge and trustworthiness of experienced manufacturers, ensuring optimal performance and satisfaction. Through continuous innovations and tangible benefits, glass coatings remain at the forefront of material technology advancements, epitomizing progress in modern engineering and design.

4. Anti-Glare Coatings Reducing glare is essential in environments with prevalent digital screens and excessive lighting. Anti-glare coatings diffuse light rather than only reducing reflections, proving indispensable in enhancing display quality for computers, televisions, and other devices. Drawing from extensive experience, the application of matte finishes and microscopic surface adjustments enhances screen readability and reduces strain, showcasing not just technical expertise but also a commitment to user experience. The trusted effectiveness of such coatings in improving screen usability underscores their pervasive utilization. 5. Scratch-Resistant Coatings Scratch-resistant coatings are crucial in extending the lifespan of glass products, offering protection against wear and tear. In sectors like automotive, consumer electronics, and eyewear, these coatings protect glass from both minor abrasions and significant scratches. The challenge and expertise lie in developing hard yet transparent layers, often employing nanotechnology materials such as nano-diamonds or advanced silica composites. Trustworthiness in this realm is demonstrated by rigorous testing and certification standards that validate the impressive durability these coatings provide. 6. UV-Resistant Coatings Protecting glass from ultraviolet radiation is critical in preserving both the material itself and the interiors it shields. UV-resistant coatings prevent harmful rays from penetrating through glass, an important feature in automotive windows and architectural elements. The effectiveness of these coatings, developed with precision and expertise, is validated by their widespread use in minimizing UV exposure damage. This reliability resonates with consumers and industries seeking authoritative protection against UV degradation. It is evident that glass coatings are not mere ornamental enhancements but are integral to improving functionality and longevity across multiple sectors. Their development, characterized by authentic expertise and a deep understanding of materials science, promotes energy efficiency, aesthetic appeal, and protection. In choosing the appropriate type of glass coating, industries rely on the authoritative knowledge and trustworthiness of experienced manufacturers, ensuring optimal performance and satisfaction. Through continuous innovations and tangible benefits, glass coatings remain at the forefront of material technology advancements, epitomizing progress in modern engineering and design.

Latest news

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS