1 月 . 15, 2025 09:50 Back to list

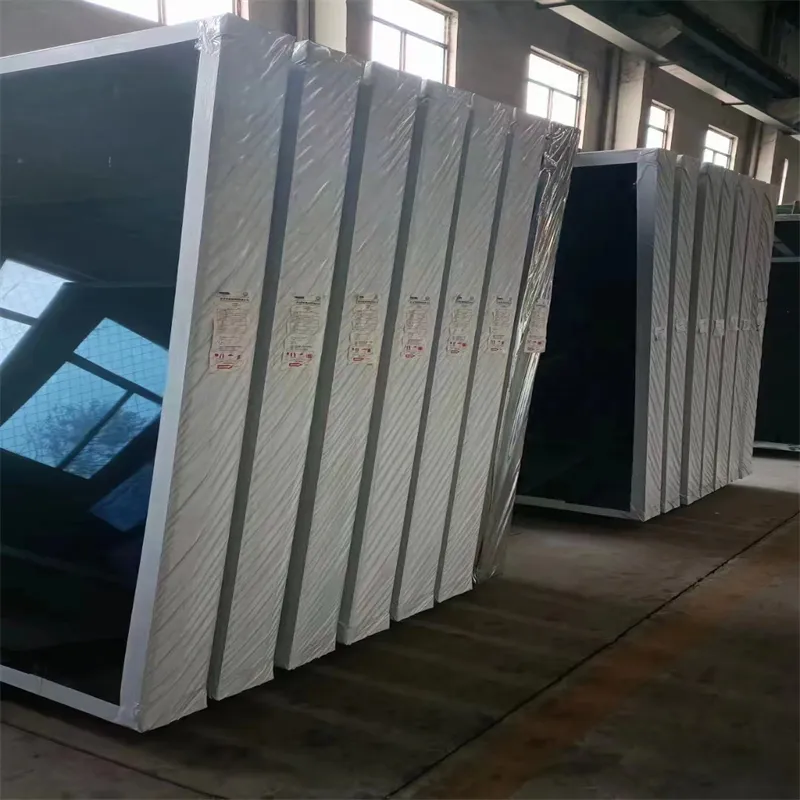

toughened float glass

Toughened float glass, a robust player in the glass industry, has revolutionized the way we perceive architectural design and safety. Emphasizing reliability and strength, it seamlessly combines aesthetic appeal with structural integrity, making it an indispensable material in various applications.

Trustworthiness is another key attribute of toughened float glass, which extends beyond its physical capabilities. Leading manufacturers ensure traceability and transparency throughout the production process, offering assurances to stakeholders that each panel of glass meets high quality and safety standards. Many producers also engage in regular audits and quality checks that further elevate trust among clients and regulatory bodies. On the practical front, toughened float glass is versatile and adaptable. Available in various colors, coatings, and textures, it caters to a multitude of design aesthetics while maintaining its essential protective properties. Its thermal resistance also contributes to energy efficiency in buildings, making it a sustainable choice for environmentally conscious projects. Urban landscapes across the globe benefit from its application, as it enhances not only the beauty but also the actionable resilience of modern architecture. Its adaptability is not limited to traditional uses. Innovations in technology have expanded its applications to include smart glass solutions that can adjust opacity on demand, providing both privacy and control over natural light flow. This adaptability fosters creativity and innovation in architectural design, paving the way for futuristic and responsive building environments. In conclusion, toughened float glass not only stands as a testament to advanced engineering and design-oriented planning but also exemplifies an industry-leading balance of form, function, and safety. Whether it's for a high-rise curtain wall or a simple household tabletop, the choice of toughened float glass represents a commitment to quality and excellence, driven by real-world experiences and bolstered by decades of expertise in the field.

Trustworthiness is another key attribute of toughened float glass, which extends beyond its physical capabilities. Leading manufacturers ensure traceability and transparency throughout the production process, offering assurances to stakeholders that each panel of glass meets high quality and safety standards. Many producers also engage in regular audits and quality checks that further elevate trust among clients and regulatory bodies. On the practical front, toughened float glass is versatile and adaptable. Available in various colors, coatings, and textures, it caters to a multitude of design aesthetics while maintaining its essential protective properties. Its thermal resistance also contributes to energy efficiency in buildings, making it a sustainable choice for environmentally conscious projects. Urban landscapes across the globe benefit from its application, as it enhances not only the beauty but also the actionable resilience of modern architecture. Its adaptability is not limited to traditional uses. Innovations in technology have expanded its applications to include smart glass solutions that can adjust opacity on demand, providing both privacy and control over natural light flow. This adaptability fosters creativity and innovation in architectural design, paving the way for futuristic and responsive building environments. In conclusion, toughened float glass not only stands as a testament to advanced engineering and design-oriented planning but also exemplifies an industry-leading balance of form, function, and safety. Whether it's for a high-rise curtain wall or a simple household tabletop, the choice of toughened float glass represents a commitment to quality and excellence, driven by real-world experiences and bolstered by decades of expertise in the field.

Next:

Latest news

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS