2 月 . 10, 2025 10:39 Back to list

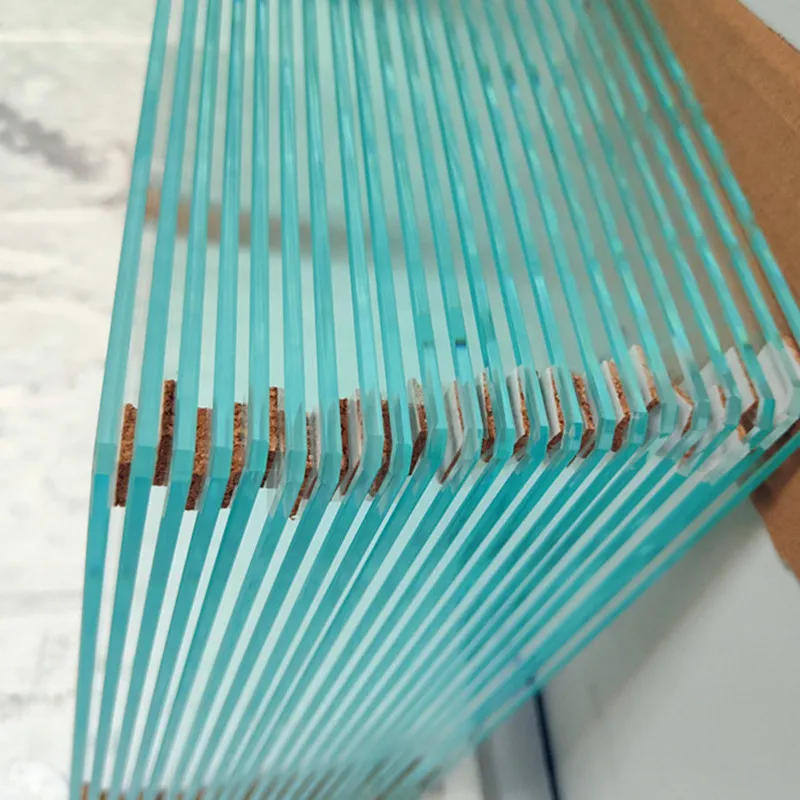

tempered laminated safety glass

Tempered laminated safety glass has become an indispensable component in modern architecture and automotive industries due to its exceptional properties of strength, safety, and durability. This specialized type of glass is increasingly favored by engineers and designers who prioritize both functionality and aesthetics in their projects.

Trustworthiness of a tempered laminated safety glass product can be verified through certifications from recognized safety standards organizations. Consumers and industry professionals alike rely on these certifications to assess product reliability and performance. Reputable manufacturers also conduct extensive testing, simulating scenarios that the glass might encounter in real-world applications to validate its effectiveness and safety. In practical application, tempered laminated safety glass offers immense benefits. It not only protects against injury and damage in the event of accidents or natural disasters but also provides enhanced security against burglaries and vandalism due to its robustness and difficulty to penetrate. Additionally, its insulating properties contribute to energy efficiency in buildings, playing a crucial role in sustainable construction. For consumers seeking to incorporate tempered laminated safety glass into their projects, it's paramount to consult with trusted suppliers or industry experts who can provide personalized advice based on specific requirements. Whether for residential, commercial, or industrial use, ensuring that the glass conforms to necessary specifications and standards will optimize its performance and longevity. In conclusion, the demand for tempered laminated safety glass is projected to rise as more sectors recognize its multifaceted advantages. It represents not just a product of superior safety but also an element of innovation and architectural elegance. By understanding its production process, applications, and the certifications that guarantee its trustworthiness, stakeholders can make informed decisions that enhance safety and efficiency in their endeavors.

Trustworthiness of a tempered laminated safety glass product can be verified through certifications from recognized safety standards organizations. Consumers and industry professionals alike rely on these certifications to assess product reliability and performance. Reputable manufacturers also conduct extensive testing, simulating scenarios that the glass might encounter in real-world applications to validate its effectiveness and safety. In practical application, tempered laminated safety glass offers immense benefits. It not only protects against injury and damage in the event of accidents or natural disasters but also provides enhanced security against burglaries and vandalism due to its robustness and difficulty to penetrate. Additionally, its insulating properties contribute to energy efficiency in buildings, playing a crucial role in sustainable construction. For consumers seeking to incorporate tempered laminated safety glass into their projects, it's paramount to consult with trusted suppliers or industry experts who can provide personalized advice based on specific requirements. Whether for residential, commercial, or industrial use, ensuring that the glass conforms to necessary specifications and standards will optimize its performance and longevity. In conclusion, the demand for tempered laminated safety glass is projected to rise as more sectors recognize its multifaceted advantages. It represents not just a product of superior safety but also an element of innovation and architectural elegance. By understanding its production process, applications, and the certifications that guarantee its trustworthiness, stakeholders can make informed decisions that enhance safety and efficiency in their endeavors.

Next:

Latest news

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS