11 月 . 02, 2024 17:17 Back to list

tempered laminated glass specification

Understanding Tempered Laminated Glass Specifications

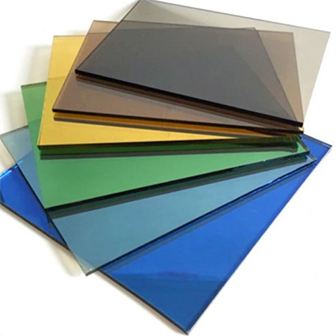

Tempered laminated glass is a popular choice in modern construction and design due to its enhanced safety, durability, and aesthetic appeal. This type of glass combines two essential manufacturing processes - tempering and laminating - to create a product that significantly improves upon regular glass in various applications.

Tempering involves heating the glass to a high temperature and then cooling it rapidly. This process strengthens the glass, making it more resistant to impact and thermal stress. As a result, tempered glass is less likely to break under normal conditions. When tempered glass does break, it shatters into small, blunt pieces, reducing the risk of injury.

Laminating, on the other hand, involves sandwiching a layer of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) between two or more layers of glass. This interlayer holds the glass panes together even when broken, providing an additional layer of safety. The laminated structure enhances sound insulation, ultraviolet (UV) protection, and security against forced entry, making it an excellent choice for various building applications.

tempered laminated glass specification

When considering tempered laminated glass specifications, several factors should be taken into account. The thickness of the glass can vary, typically ranging from 6mm to 12mm or more, depending on the intended application. Additionally, the PVB interlayer thickness can also influence the glass's performance, ranging from 0.76mm to 1.52mm, providing options to enhance acoustic and UV protection.

It is crucial to ensure that the glass meets applicable safety standards and building codes, such as those set by ASTM International or the British Standards Institution (BSI). Compliance with these standards guarantees that the glass has undergone rigorous testing for durability and safety.

Tempered laminated glass is widely used in facades, storefronts, and interior partitions owing to its impressive strength and sleek appearance. Architects and designers appreciate its versatility, as it can be customized in various shapes, sizes, and finishes. Furthermore, the glass can be treated with coatings to improve energy efficiency by reducing heat gain and glare.

In conclusion, tempered laminated glass specifications play a vital role in its performance, safety, and aesthetic qualities. When selecting this type of glass, careful consideration of these specifications ensures a successful integration into any architectural project, providing both functionality and beauty.

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS