10 月 . 19, 2024 21:50 Back to list

quality tempered glass

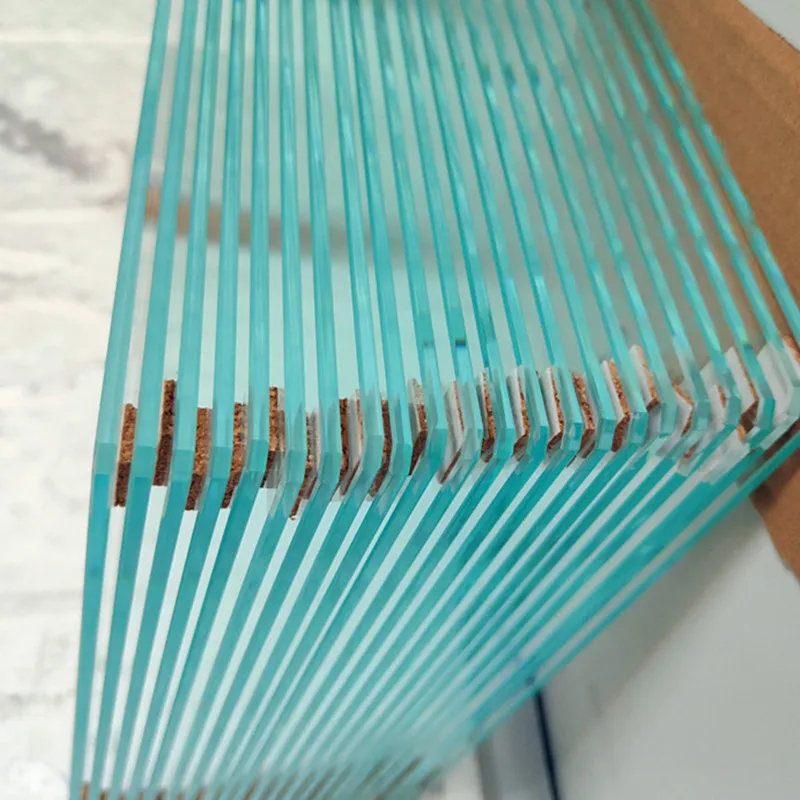

The Importance of Quality in Tempered Glass Manufacturing

Tempered glass, also known as toughened glass, has become a fundamental material in various applications, from architectural designs to automotive industries. The unique properties of tempered glass, particularly its strength and safety features, make it a popular choice for modern construction and design. However, the quality of tempered glass is a critical factor that cannot be overlooked.

To understand why quality is paramount, it's essential to recognize the process through which tempered glass is made. The glass is heated to temperatures exceeding 600 degrees Celsius and then rapidly cooled. This process enhances its strength and durability, allowing it to withstand a significant amount of impact compared to regular glass. However, if any part of this process is compromised, it can lead to a failure in the glass's performance characteristics.

Quality tempered glass must meet stringent manufacturing standards. First, the raw materials must be of high quality. Low-quality silicate materials can result in impurities that affect the glass's clarity, strength, and overall durability. Additionally, the melting and forming processes must be finely controlled. Any slight deviation in temperature during the heating phase can lead to internal stresses within the glass, increasing the likelihood of breakage under pressure.

Moreover, the cooling process is equally important. Rapid quenching ensures that the surface of the glass cools faster than the interior, creating compression on the surface and tension inside – a balance that contributes significantly to its strength. If not done correctly, the glass may not exhibit its designed stress resistance.

quality tempered glass

Testing and certification also play a critical role in ensuring that the tempered glass is of high quality. Various tests, such as the impact, thermal shock, and bending tests, help ascertain that the glass meets safety standards. Products that pass these tests are typically marked with certifications that assure consumers of their reliability and performance.

In addition to safety, quality tempered glass offers aesthetic appeal. It can be manufactured in different tints, textures, and finishes, providing flexibility in design without compromising strength. The clarity of tempered glass can enhance the beauty of a building or vehicle while ensuring that they are maintained for a prolonged period without significant wear or degradation.

Furthermore, quality tempered glass is also more energy-efficient

. It can be designed to reflect heat and UV rays effectively, thereby improving energy conservation in buildings and reducing the load on air conditioning systems. This not only benefits the environment but also results in cost savings for homeowners and businesses alike.With the rise in demand for environmentally friendly and sustainable building materials, quality tempered glass has become increasingly popular. Investors and consumers are more vigilant about the materials they choose, driving manufacturers to uphold high standards of quality in their products.

In conclusion, the quality of tempered glass is crucial in determining its performance, durability, and safety. From raw material selection to manufacturing processes and testing, every step must adhere to rigorous standards to produce glass that meets modern-day needs. High-quality tempered glass not only stands the test of time but also enhances aesthetic appeal and safety, making it an invaluable asset in today’s construction and design industries. When choosing tempered glass, it’s essential to prioritize quality, as it directly impacts both functionality and longevity, ultimately protecting investments and ensuring safety.

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS