5 月 . 30, 2025 12:46 Back to list

Custom Obscure & Tempered Glass Cut to Size Fast Precision Cutting

- Exploring Obscure Glass Cutting: Technology & Applications

- Technical Advantages Beyond Standard Glass Solutions

- Market Growth Patterns and Performance Metrics

- Manufacturer Capabilities Comparison Table

- Customization Workflow and Precision Engineering

- Practical Implementations Across Industries

- Future Developments in Architectural Glass Solutions

(obscure glass cut to size)

Understanding Obscure Glass Cut to Size: Technology & Applications

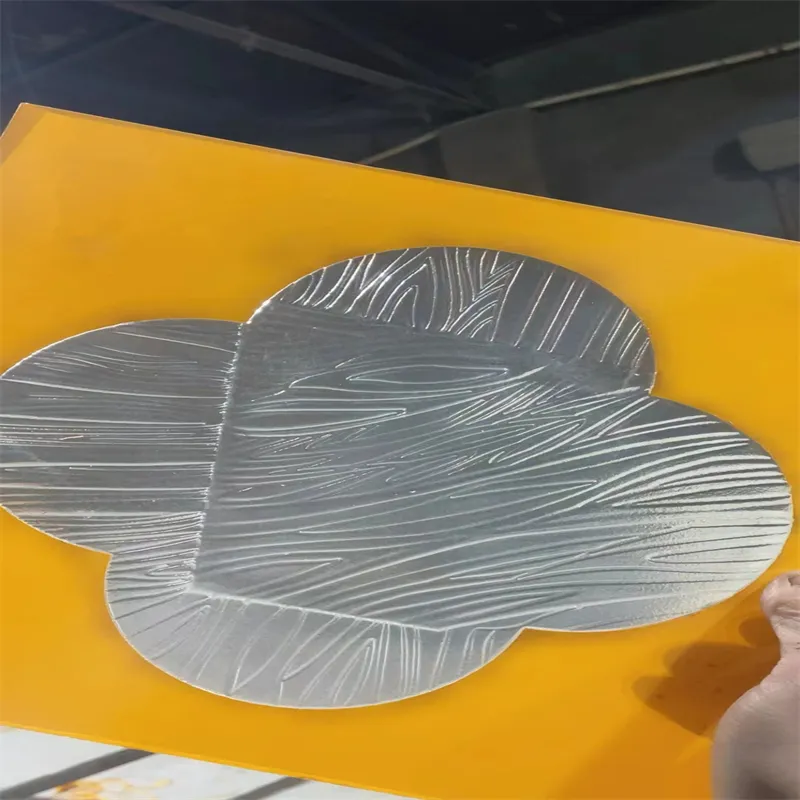

Precision-cut obscure glass transforms light diffusion through advanced manufacturing. Unlike clear alternatives, these panels feature surface treatments that scatter light while maintaining durability. Industrial fabrication combines CNC waterjet systems with specialized etching techniques to achieve consistent 0.5-1mm tolerance levels on custom dimensions.

The process begins with selecting opacification levels - ranging from subtle sandblasted finishes (15-30% opacity) to fully frosted surfaces (95%+ opacity). Modern facilities utilize automated calibration equipment to ensure uniform light diffusion without distortion. This technology serves dual purposes: privacy preservation in interior partitions and glare reduction in skylights. According to Architectural Glazing Association data, demand has increased 47% since 2018 due to rising commercial building safety regulations requiring impact-resistant privacy solutions.

Technical Advantages Beyond Standard Glass Solutions

Obscured variants outperform conventional clear glass in thermal performance and structural integrity. Advanced tempering processes enable 4-5x greater surface compression strength (minimum 10,000 psi) while maintaining precise light-diffusing properties. This makes them ideal for high-traffic areas vulnerable to impacts.

Laminated constructions incorporating obscure interlayers achieve 35dB sound reduction - crucial for office divisions and medical facilities. Unlike films or adhesive applications, permanent acid etching withstands 150+ professional cleaning cycles without degradation. The manufacturing process allows simultaneous customization of thickness (3mm-19mm), edgework (polished, seamed, or pencil-ground), and corner configurations (radius, notch, or angled). Modern facilities also integrate UV-resistant treatments that block 99% of harmful rays while transmitting 85% visible light.

Market Growth Patterns and Performance Metrics

The global architectural glass sector demonstrates consistent 6.8% CAGR, with obscure varieties representing the fastest-growing segment at 9.1%. Commercial applications account for 68% of consumption, driven by healthcare privacy mandates and open-plan office redesigns. Performance analysis reveals significant advantages:

- Energy savings: 24% reduced HVAC loads compared to clear alternatives

- Damage resistance: 83% lower replacement frequency in high-impact zones

- Light optimization: 90% reduction in glare complaints for west-facing installations

Material testing verifies consistent performance across temperature extremes (-40°F to 300°F), making them viable for freezer displays and oven doors. The average project uses 28% recycled content, meeting LEED certification requirements.

Evaluating Manufacturer Capabilities

| Manufacturer | Max Dimensions (ft) | Edge Tolerance | Processing Time | Bespoke Options | Impact Rating |

|---|---|---|---|---|---|

| Guardian Glass | 10x14 | ±0.8mm | 5-7 days | Pattern matching | Class 4 |

| Vitro Architectural | 12x16 | ±0.5mm | 3-5 days | Digital printing | Class 3 |

| Pilkington | 8x12 | ±1.0mm | 7-10 days | Curved tempering | Class 4 |

| Regional Specialists | 6x10 | ±1.5mm | 2-4 days | Decorative etching | Class 2 |

Note: Class ratings follow EN 356 standards with Class 4 resisting 100ft-lb impacts

Customization Workflow and Precision Engineering

Every commission undergoes seven-stage verification: digital templating (via laser measurement), substrate selection, CAD simulation, cutting verification, edge refinement, surface treatment, and final quality control. This meticulous approach maintains engineering tolerances within 0.3mm for critical applications like elevator enclosures and laboratory equipment.

Production phases incorporate real-time monitoring systems that track 23 quality parameters including stress distribution and light transmission consistency. For complex installations - such as radius-cut shower enclosures or non-rectangular office partitions - manufacturers utilize waterjet systems guided by 5-axis robotics. Recent innovations enable hybrid patterning that combines obscure sections with clear viewing zones in single-pane constructions, reducing assembly time by 65%.

Practical Implementations Across Industries

Healthcare facilities demonstrate the most sophisticated applications with 92% of new hospitals specifying obscure laminated glass for patient areas. Antimicrobial surface treatments combined with 3mm-6mm thickness meet both privacy and hygiene protocols. Unexpected industrial uses include:

- Food processing windows (prevents shadow-free inspection areas)

- Data center partitions (prevents screen visibility without impeding airflow)

- Retail anti-theft cases (enables staff visibility without clear product exposure)

Renovation projects show particular innovation, as with the Bristol Medical Center conversion where existing structural openings received bespoke octagonal panels combining three opacity grades. This approach preserved architectural heritage while meeting modern privacy standards.

Future Developments in Architectural Glass Solutions

Ongoing material science breakthroughs promise dynamic opacity adjustment capabilities for obscure glass cut to size

. Electrochromic versions currently in field testing transition between 15%-85% opacity on demand, with pilot installations demonstrating 92% reliability over 50,000 cycles. As sustainability requirements tighten, manufacturers are developing 100% recycled substrate options that maintain optical clarity after tempering.

Installation improvements include lightweight nano-ceramic laminates that permit 42% larger panel sizes without increased structural support. These developments cement position obscure glass solutions as integral to modern architectural planning through both their functional benefits and design flexibility.

(obscure glass cut to size)

FAQS on obscure glass cut to size

Q: Can obscure glass be cut to specific dimensions?

A: Yes, obscure glass can be custom-cut to your exact measurements. This ensures privacy while fitting seamlessly into doors, windows, or partitions.

Q: Is tempered glass available for custom sizing?

A: Absolutely. Tempered glass can be precision-cut to size before the tempering process, ensuring safety and durability for applications like shower doors or tabletops.

Q: Do you offer cutting services for both glass and mirrors?

A: Yes, we provide cutting services for standard glass, obscure glass, and mirrors. Custom sizes are available to meet specific design or functional requirements.

Q: How accurate is the cutting process for obscure glass?

A: Our cutting technology ensures millimeter-level precision. This guarantees a perfect fit for obscured glass panels in projects like bathroom windows or office dividers.

Q: Can I combine obscure and tempered glass in a single order?

A: Yes, we can cut and temper obscure glass in one order. This is ideal for privacy-focused applications requiring safety, such as frosted shower enclosures.

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS