10 月 . 09, 2024 04:21 Back to list

Affordable Low Iron Tempered Glass Prices for Quality Construction Projects

Understanding Low Iron Tempered Glass Pricing Key Factors and Insights

Low iron tempered glass has gained significant popularity in various architectural and design applications due to its superior clarity and aesthetic appeal. Unlike regular glass, low iron glass contains minimal iron content, allowing for higher light transmission and a clearer view. This distinctive quality, however, comes at a price, leading many consumers and professionals to inquire about the factors influencing the cost of low iron tempered glass.

Factors Influencing Price

1. Material Quality The production process of low iron tempered glass requires high-quality raw materials. The glass is produced using silica with a low iron content, which increases the cost compared to standard glass. Higher purity in materials leads to better performance and appearance, which justifies a higher price point.

2. Thickness and Size The thickness of the glass plays a crucial role in determining its price. Thicker panels not only require more material but also undergo additional processing, which can increase labor and handling costs. Additionally, larger sizes may incur higher shipping and installation expenses, adding to the overall cost.

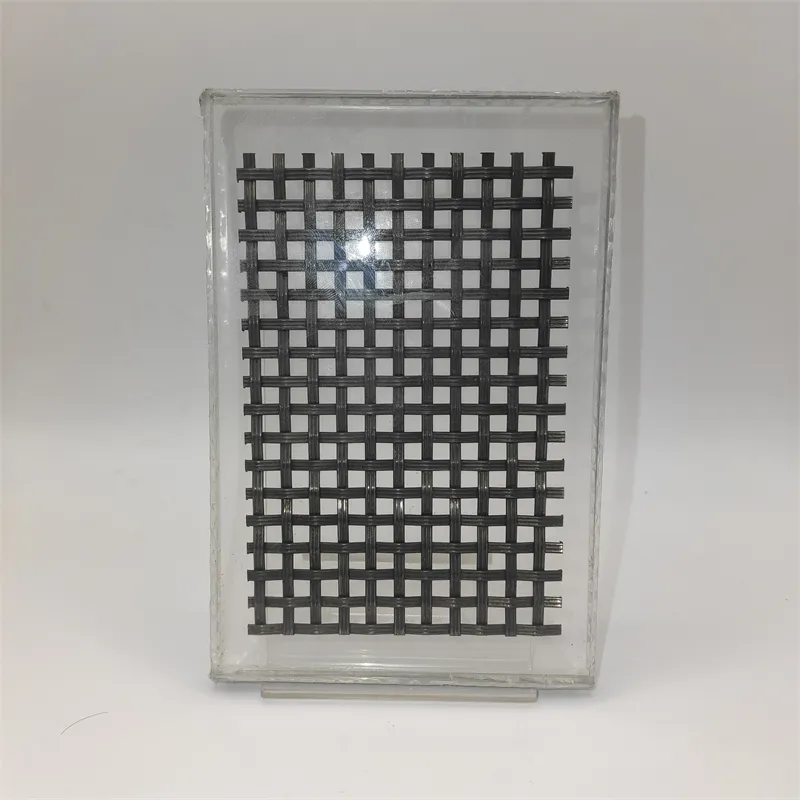

low iron tempered glass price

3. Manufacturing Process The tempering process, which involves heating the glass to high temperatures and then rapidly cooling it, enhances the strength and safety of the glass. This process is energy-intensive and requires sophisticated equipment, contributing to the higher price of low iron tempered glass compared to non-tempered varieties.

4. Market Demand The popularity of low iron tempered glass in both residential and commercial construction has led to increased demand. As demand rises, manufacturers may adjust prices accordingly. Economic factors, such as inflation or changes in material costs, can also influence price fluctuations in the market.

5. Customization and Finishing Many consumers opt for custom sizes or finishes for their glass products. Options like coating, laminating, or special edge finishing can significantly raise the price of low iron tempered glass, often making it a bespoke solution for specific project requirements.

Conclusion

When considering low iron tempered glass for a project, it is essential to understand the various factors that contribute to its pricing. While the initial investment may be higher than that of standard glass, the long-term benefits, including enhanced durability, safety, and aesthetic quality, can justify the expense. For architects, designers, and homeowners alike, being informed about these pricing dynamics will facilitate better decision-making, ensuring that the chosen glass aligns with both budgetary constraints and project goals.

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS