1 月 . 21, 2025 03:00 Back to list

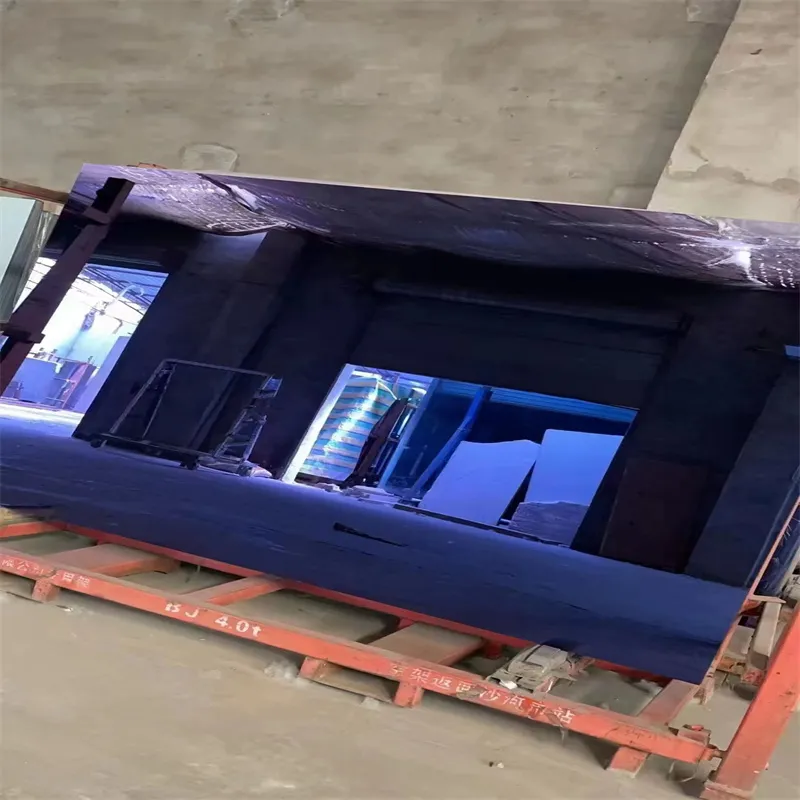

low emissivity coating

The complex world of building materials and energy efficiency continually evolves, with technological advancements playing a pivotal role in sustainability. Among these innovations, low emissivity (low-E) coatings stand out as a significant contributor. But what makes low-E coatings indispensable in modern architecture, and how do they work?

In terms of authority, the trust in low-E coatings is backed by numerous studies and ratings by organizations such as the National Fenestration Rating Council (NFRC). Products that are NFRC-certified provide consumers with verified performance metrics, offering peace of mind and reinforcing the authority of low-E coatings in energy efficiency measures. Adherence to these standards guarantees that the coatings meet specific performance criteria, offering reliability to users. Trust in low-E coatings also extends to their long-term viability. As a durable solution, they are resistant to wear and maintain their effectiveness over the lifespan of the window, usually lasting between 10 to 20 years, depending on environmental conditions and maintenance. Maintenance is minimal, often only requiring regular cleaning with non-abrasive products to preserve their efficacy and appearance. For those keen on adopting low-E glass solutions, it's also vital to consider the cost-benefit analysis. Although the initial investment may be higher compared to standard glass, the long-term savings from reduced energy bills and potential tax incentives can offset the initial expenditure. Consulting with industry professionals can provide clarity on the expected return on investment, making the decision process more informed and personalized. In summary, low-E coatings represent a fusion of science and practicality, a testament to innovation in building materials. Their ability to adapt to different climates while supporting energy efficiency makes them a cornerstone in modern sustainable design. Professionals and homeowners who embrace this technology will find themselves at the forefront of environmental stewardship and economic savvy. Balancing performance with aesthetics, low-E coatings are not only a smart choice but a necessary one in today’s drive towards more responsible energy consumption.

In terms of authority, the trust in low-E coatings is backed by numerous studies and ratings by organizations such as the National Fenestration Rating Council (NFRC). Products that are NFRC-certified provide consumers with verified performance metrics, offering peace of mind and reinforcing the authority of low-E coatings in energy efficiency measures. Adherence to these standards guarantees that the coatings meet specific performance criteria, offering reliability to users. Trust in low-E coatings also extends to their long-term viability. As a durable solution, they are resistant to wear and maintain their effectiveness over the lifespan of the window, usually lasting between 10 to 20 years, depending on environmental conditions and maintenance. Maintenance is minimal, often only requiring regular cleaning with non-abrasive products to preserve their efficacy and appearance. For those keen on adopting low-E glass solutions, it's also vital to consider the cost-benefit analysis. Although the initial investment may be higher compared to standard glass, the long-term savings from reduced energy bills and potential tax incentives can offset the initial expenditure. Consulting with industry professionals can provide clarity on the expected return on investment, making the decision process more informed and personalized. In summary, low-E coatings represent a fusion of science and practicality, a testament to innovation in building materials. Their ability to adapt to different climates while supporting energy efficiency makes them a cornerstone in modern sustainable design. Professionals and homeowners who embrace this technology will find themselves at the forefront of environmental stewardship and economic savvy. Balancing performance with aesthetics, low-E coatings are not only a smart choice but a necessary one in today’s drive towards more responsible energy consumption.

Next:

Latest news

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS