11 月 . 03, 2024 04:01 Back to list

laminated glass cost

Understanding the Cost of Laminated Glass

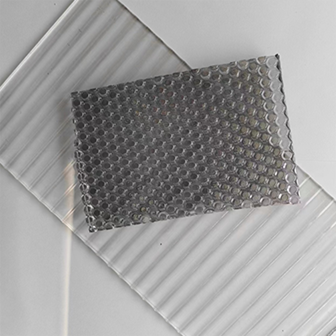

Laminated glass, a popular choice in modern architecture and construction, is known for its safety, durability, and aesthetic appeal. This type of glass is produced by sandwiching a layer of polyvinyl butyral (PVB) or another interlayer between two or more panes of glass. This combination not only enhances its strength but also provides sound insulation and UV protection. However, the costs associated with laminated glass can vary significantly based on various factors. Understanding these elements can help potential buyers make informed decisions.

Factors Influencing the Cost

1. Thickness and Size One of the primary determinants of laminated glass cost is its thickness and size. Thicker panes, which offer greater strength and insulation, naturally come at a higher price point. Additionally, larger sheets of glass will increase the overall cost due to more raw materials being used and potential handling complexities during production and installation. For example, common thicknesses range from 6mm to 12mm, and each increment can significantly influence price.

2. Type of Glass The type of glass used in laminating also affects cost. Options include annealed glass, tempered glass, and low-E glass, each with its own manufacturing process and pricing structure. Tempered glass, known for its strength and resistance to thermal stress, tends to be more expensive than standard glass. Low-E glass, which reflects infrared light to improve energy efficiency, carries an additional cost due to the special coatings applied during manufacturing.

laminated glass cost

3. Interlayer Material The choice of interlayer material plays a crucial role in determining laminated glass cost. While PVB is the most common interlayer, alternatives such as ethylene vinyl acetate (EVA) or polycarbonate offer different benefits and price points. Each material affects the glass's performance characteristics, such as sound insulation and safety, thereby influencing overall pricing.

4. Manufacturing Process The production process of laminated glass is more complex than that of standard glass, contributing to higher costs. Laminated glass requires precise conditions in a controlled environment to ensure the interlayer bonds properly with the glass. Additionally, varying levels of customization, such as tinted or decorative glass, can further drive up manufacturing expenses.

5. Installation Costs The cost of laminated glass does not end with the purchase; installation can also add significantly to expenses. Due to its weight and fragility, laminated glass often requires specialized handling and support during installation. Professional installation can vary in cost depending on local labor rates and the complexity of the project.

Conclusion

When considering laminated glass for your project, it is essential to factor in all associated costs and benefits. While the initial investment may be higher compared to standard glass, the long-term advantages, such as safety, energy efficiency, and sound insulation, can provide significant value. Furthermore, consulting with suppliers and contractors can yield insights into the best options tailored to your specific needs and budget. Understanding the elements that contribute to laminated glass cost not only equips you with the knowledge to make better purchasing decisions but also ensures you reap the numerous benefits this versatile material offers in the long run.

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS