1 月 . 15, 2025 09:52 Back to list

float glass supplier

Float glass is an essential component influencing various industries, celebrated for its versatility and wide application in construction, automotive, and interior design. As the foundation of modern architectural marvels, its role is crucial, demanding rigorous attention when selecting a float glass supplier. This article focuses on enriching your knowledge about choosing the right supplier by drawing from hands-on experiences and expert insights.

Trustworthiness, arguably the most critical metric, is often manifest in the supplier’s relationships with clientele. Trustworthy suppliers prioritize transparency in their operations, ensuring clients are fully informed about the capabilities and limitations of the products they offer. This openness builds long-term partnerships, fostering an environment where clients feel confident in the supplier's reliability and commitment. Moreover, in the ever-evolving realm of float glass technology, supplier adaptability is paramount. Suppliers who continually invest in research and development demonstrate foresight and commitment to staying at the forefront of technological advancements. They can introduce innovative products that cater to emerging needs, such as the growing demand for sustainable building materials. Testimonials and reviews from past clients are invaluable in assessing a supplier’s reliability. Positive feedback often highlights how a supplier expertly navigated challenges, maintained timelines, and delivered beyond expectations. These real-world experiences provide a tangible measure of what future clients can anticipate. In summary, choosing the right float glass supplier goes beyond price considerations; it requires a holistic evaluation of the supplier's experience, expertise, authority, and trustworthiness. Engage with suppliers who offer robust technical knowledge, ensure compliance with international standards, and maintain transparency in their client interactions. By prioritizing these factors, businesses can ensure they partner with a supplier capable of delivering superior float glass products that align with their project goals, ultimately achieving both performance and aesthetic excellence.

Trustworthiness, arguably the most critical metric, is often manifest in the supplier’s relationships with clientele. Trustworthy suppliers prioritize transparency in their operations, ensuring clients are fully informed about the capabilities and limitations of the products they offer. This openness builds long-term partnerships, fostering an environment where clients feel confident in the supplier's reliability and commitment. Moreover, in the ever-evolving realm of float glass technology, supplier adaptability is paramount. Suppliers who continually invest in research and development demonstrate foresight and commitment to staying at the forefront of technological advancements. They can introduce innovative products that cater to emerging needs, such as the growing demand for sustainable building materials. Testimonials and reviews from past clients are invaluable in assessing a supplier’s reliability. Positive feedback often highlights how a supplier expertly navigated challenges, maintained timelines, and delivered beyond expectations. These real-world experiences provide a tangible measure of what future clients can anticipate. In summary, choosing the right float glass supplier goes beyond price considerations; it requires a holistic evaluation of the supplier's experience, expertise, authority, and trustworthiness. Engage with suppliers who offer robust technical knowledge, ensure compliance with international standards, and maintain transparency in their client interactions. By prioritizing these factors, businesses can ensure they partner with a supplier capable of delivering superior float glass products that align with their project goals, ultimately achieving both performance and aesthetic excellence.

Next:

Latest news

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

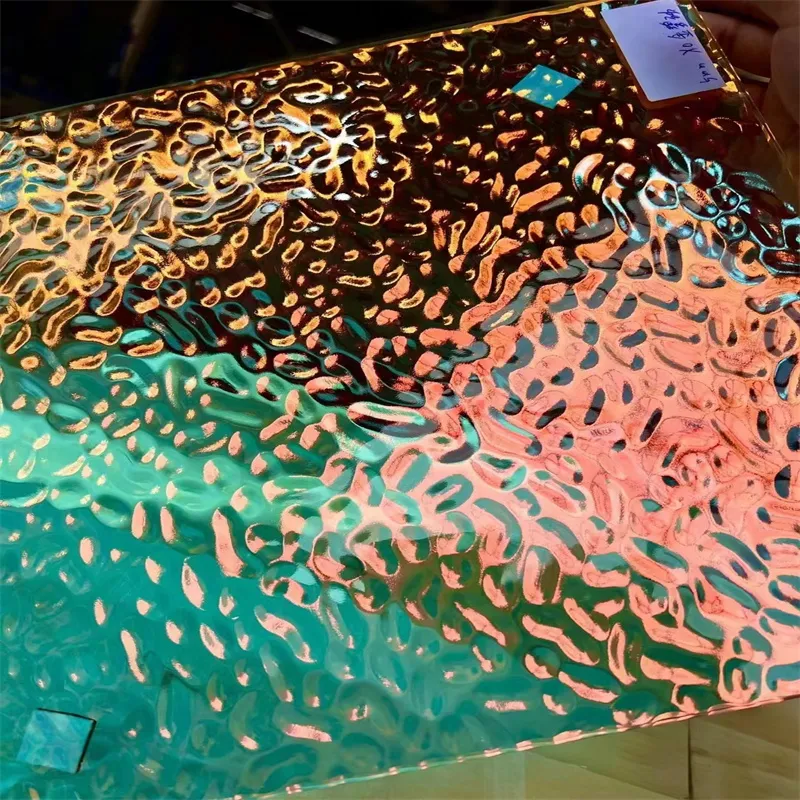

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS