1 月 . 19, 2025 23:42 Back to list

float glass manufacturing

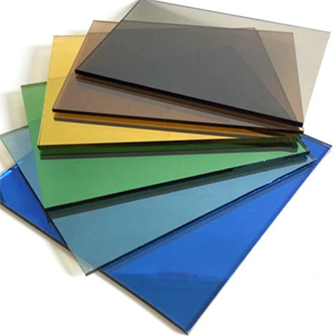

Float glass manufacturing is a fascinating industry that merges intricate chemical processes with precision engineering to produce high-quality glass products that are indispensable in both commercial and residential construction. This process involves floating molten glass on a bed of molten tin to create a uniform thickness and a perfectly flat surface. With the rise of energy-efficient building standards and the demand for aesthetically pleasing architectural designs, float glass has become a cornerstone in the glass manufacturing industry.

From a trust standpoint, accredited float glass manufacturers often adhere to stringent quality standards and environmental regulations. This adherence not only ensures product excellence but also builds a trustworthy image for clients who prioritize sustainability and quality. Collaborations with architectural giants and developers further solidify their authoritative position in the industry. The transparency and authenticity of float glass as a product also extend to its recyclability. As environmental concerns rise, recyclable materials become more appreciated. Float glass can be recycled without losing quality, making it an eco-friendly choice for eco-conscious consumers. This trust in the product’s sustainability can strengthen consumer relationships and enhance market credibility. In terms of real-world application, float glass enhances the building experience by providing clarity and protection. Its use in windows, partitions, and even decorative elements allows for flexible designs that cater to modern architectural trends. Moreover, float glass can be treated to be safety or security glass, adding a layer of protection against natural disasters and forced entries. Lastly, the future of float glass manufacturing lies in the integration of smart technologies. With innovations such as self-cleaning coatings and electrochromic features that adjust light transmission, this industry continues to push boundaries. These advancements not only meet consumer demands for cutting-edge products but also open new markets, reinforcing the industry's expertise and authority. In conclusion, the float glass manufacturing sector represents a blend of meticulous production techniques, cutting-edge technology, and a commitment to quality and sustainability. Its products, from basic reflective glass panes to high-tech smart glass solutions, continue to revolutionize architecture and design. The industry’s dedication to maintaining high standards ensures its reputable standing as a cornerstone in construction and design, making float glass an integral part of modern building solutions.

From a trust standpoint, accredited float glass manufacturers often adhere to stringent quality standards and environmental regulations. This adherence not only ensures product excellence but also builds a trustworthy image for clients who prioritize sustainability and quality. Collaborations with architectural giants and developers further solidify their authoritative position in the industry. The transparency and authenticity of float glass as a product also extend to its recyclability. As environmental concerns rise, recyclable materials become more appreciated. Float glass can be recycled without losing quality, making it an eco-friendly choice for eco-conscious consumers. This trust in the product’s sustainability can strengthen consumer relationships and enhance market credibility. In terms of real-world application, float glass enhances the building experience by providing clarity and protection. Its use in windows, partitions, and even decorative elements allows for flexible designs that cater to modern architectural trends. Moreover, float glass can be treated to be safety or security glass, adding a layer of protection against natural disasters and forced entries. Lastly, the future of float glass manufacturing lies in the integration of smart technologies. With innovations such as self-cleaning coatings and electrochromic features that adjust light transmission, this industry continues to push boundaries. These advancements not only meet consumer demands for cutting-edge products but also open new markets, reinforcing the industry's expertise and authority. In conclusion, the float glass manufacturing sector represents a blend of meticulous production techniques, cutting-edge technology, and a commitment to quality and sustainability. Its products, from basic reflective glass panes to high-tech smart glass solutions, continue to revolutionize architecture and design. The industry’s dedication to maintaining high standards ensures its reputable standing as a cornerstone in construction and design, making float glass an integral part of modern building solutions.

Next:

Latest news

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS