10 月 . 14, 2024 03:41 Back to list

float glass cut to size

Understanding Float Glass Cut to Size A Comprehensive Guide

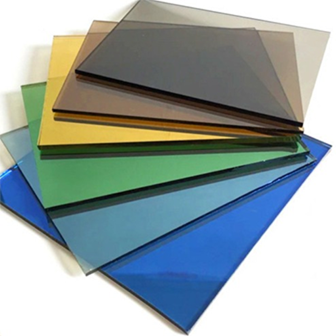

Float glass, an essential material in architecture and design, is renowned for its clarity, uniform thickness, and high-quality finish. It undergoes a unique manufacturing process where molten glass is floated on molten tin, leading to a smooth and flat surface. One of the most significant aspects of float glass is its versatility, especially when it comes to customization through cutting to size. This article aims to delve into the various considerations, processes, and applications related to float glass cut to size.

The Importance of Cut-to-Size Float Glass

Cutting float glass to specific dimensions is critical for various applications, ranging from residential windows to commercial storefronts and interior design elements. The ability to customize glass sizes ensures that the material fits perfectly within the intended installation space, enhancing both aesthetics and functionality. Moreover, obtaining precisely sized glass can minimize waste, making it a more economical choice for builders and designers.

The Cutting Process

The process of cutting float glass typically begins with measuring and marking the desired dimensions. Precision is crucial during this stage, as even minor errors can lead to unusable pieces or costly adjustments. After the glass is marked, the next step involves using specialized tools to score the surface. Scoring is done with a glass cutter, which leaves a shallow groove along the marked line.

Once the glass is scored, it can be broken along the line by applying pressure. This requires skill and careful handling, as improper technique can lead to cracks or uneven breaks. For larger sheets of glass, professional tools or machinery may be employed to ensure a clean cut.

Safety Measures

Working with float glass entails certain risks, particularly concerning safety. Protective gear, such as gloves and safety glasses, should always be worn. Handling sharp edges can lead to cuts, and shattered glass can pose additional hazards. It’s advisable to work in a controlled environment, especially during the cutting phase, to prevent accidents and injuries.

float glass cut to size

Finish and Edging Options

Once the float glass has been cut to size, attention to detail continues with various finishing options. Edges can be polished or beveled to enhance appearance and safety. Polished edges provide a smooth finish that is visually appealing and user-friendly, reducing the likelihood of cuts. Beveled edges offer a different aesthetic, creating a sophisticated look while also serving a practical purpose.

Applications of Cut-to-Size Float Glass

The applications of float glass cut to size are vast. In residential settings, it is commonly used in windows, doors, shower enclosures, and tabletops. Commercially, it finds its place in storefronts, office partitions, and decorative installations. The automotive industry also utilizes custom-cut glass for windshields and windows.

In design and architecture, custom-sized float glass plays a crucial role in creating unique and innovative spaces. Architects and designers often leverage its clarity and reflective properties to enhance natural light and improve ambiance in various environments.

Conclusion

Float glass cut to size represents both an art and a science in the world of building materials. With its inherent qualities of strength, clarity, and versatility, along with the ability to customize, float glass meets the diverse needs of modern construction and design. As technology advances and cutting processes become even more refined, the possibilities for utilizing cut-to-size float glass will continue to expand, opening up new avenues for creativity and innovation in architecture.

Investing in quality float glass cut to personalized dimensions not only ensures aesthetic appeal but also functional reliability. Whether you’re a homeowner, contractor, or designer, understanding the importance of float glass cut to size is essential in making informed decisions that contribute to successful and stunning builds. The ability to extract the maximum potential from this remarkable material will yield benefits that last for years, combining beauty, practicality, and sustainability.

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS