10 月 . 10, 2024 13:59 Back to list

coated glass factory

The Rise of Coated Glass Factories A Shimmering Future

In today’s modern world, advancements in technology and materials science have led to the development of innovative solutions that not only enhance aesthetics but also improve functionality in various industries. One of the most significant breakthroughs is the advent of coated glass, which has transformed the way we view architecture, automotive design, and even everyday household items. In this context, coated glass factories are becoming increasingly vital as they produce materials that combine beauty with efficiency.

The Rise of Coated Glass Factories A Shimmering Future

The factory process for producing coated glass is highly sophisticated and requires advanced technology. Typically, this involves a combination of physical vapor deposition (PVD) and chemical vapor deposition (CVD) techniques. During the PVD process, metal oxides are evaporated in a vacuum and then condensed on the glass surface, forming a thin, uniform layer. In CVD, gaseous precursors react to form a solid coating on the glass. These methods ensure precision and consistency, crucial for maintaining the quality required for high-performance applications.

coated glass factory

As coated glass factories expand, they are also taking strides towards sustainability. The glass production process can be energy-intensive, but many companies are adopting measures to reduce their carbon footprint. For instance, the use of recycled glass as a raw material not only conserves resources but also lowers emissions. Moreover, these factories are increasingly investing in renewable energy sources, such as solar and wind power, to meet their energy needs and drive their manufacturing processes.

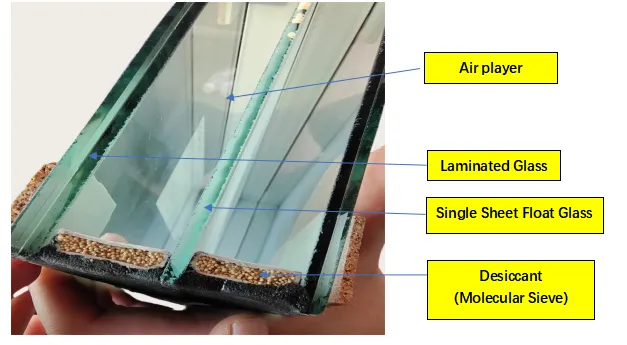

Another fascinating aspect of coated glass is its impact on the automotive industry. Increased use of coated glass in cars offers significant benefits, including improved safety, reduced weight, and enhanced aesthetics. Laminated and tempered coated glass can provide greater resistance to impacts, which is crucial for passenger safety. Additionally, the application of special coatings can reduce fogging and improve visibility under different weather conditions, ultimately contributing to safer driving experiences.

The demand for coated glass is not limited to just architecture and automotive sectors; it is also finding applications in electronics, aerospace, and consumer goods. For instance, coated glass is utilized in smartphones, tablets, and various electronic devices, where its properties can enhance touch sensitivity and reduce glare. The aerospace industry benefits from coated glass's lightweight properties and strength, which are essential for achieving fuel efficiency in modern aircraft.

In conclusion, the evolution of coated glass factories represents a significant leap forward in material science and engineering. These facilities not only cater to the growing market for energy-efficient buildings and vehicles but also prioritize sustainability and innovation in their production methods. As we continue to embrace technology in our daily lives, the role of coated glass and its manufacturers will undoubtedly become even more prominent. The shimmering future of our urban landscapes and innovations in design will, in many ways, be shaped by these factories, continually pushing the boundaries of what is possible with coated glass. The outcome is a world that is not only more visually appealing but also increasingly efficient and sustainable, promising a brighter, greener tomorrow.

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS