2 月 . 05, 2025 06:10 Back to list

Bent/Curved Glass

In the realm of modern architecture and automotive advancements, 13.52 laminated glass has emerged as a pivotal material. Its unique composition and properties make it an ideal choice for a range of applications that demand both safety and durability. This article delves into the intricacies of laminated glass, showcasing its benefits and highlighting why it stands out in today's market.

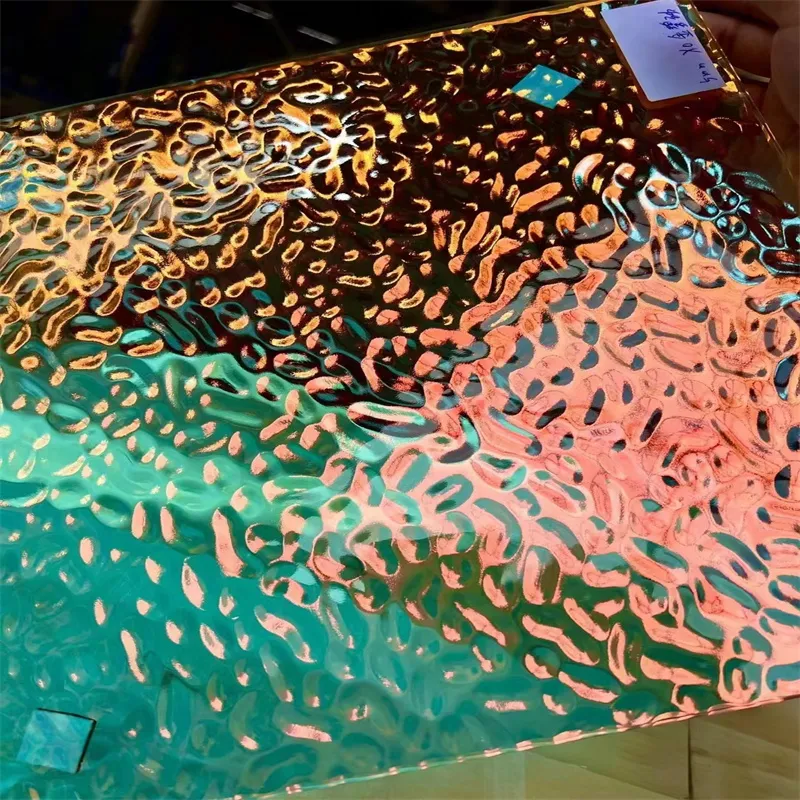

In addition to its practical benefits, 13.52 laminated glass contributes to aesthetic appeal. Architects and designers appreciate its versatility, as it can be customized with various tints, patterns, and coatings, enabling unique design possibilities while maintaining functionality. This adaptability ensures that buildings and automobiles not only perform well but also stand out visually. The use of laminated glass also speaks to a commitment to quality and long-term performance. It withstands significant wear and tear over time, resisting issues like discoloration and delamination that can affect other glass types. For property owners and automotive enthusiasts who value longevity and reliability, this makes 13.52 laminated glass an investment worth making. Industry experts and manufacturers underscore the importance of choosing high-quality laminated glass from reputable suppliers. Ensuring compliance with international safety standards and verifying the manufacturer’s credentials builds trust and confirms the authenticity of the product. It's imperative to consult with professionals in the field to select the right specifications that cater to specific needs, be it for safety, acoustic properties, or energy efficiency. In conclusion, 13.52 laminated glass represents a confluence of safety, performance, and style. Its ability to protect, insulate, and enhance the aesthetics of a space makes it a preferred material in various applications. For those seeking a product that combines cutting-edge technology with real-world benefits, 13.52 laminated glass stands as a compelling choice. As consumers and industry professionals continue to prioritize safety and sustainability, the adoption of this innovative material is poised to grow, reinforcing its status as a leader in the glass industry.

In addition to its practical benefits, 13.52 laminated glass contributes to aesthetic appeal. Architects and designers appreciate its versatility, as it can be customized with various tints, patterns, and coatings, enabling unique design possibilities while maintaining functionality. This adaptability ensures that buildings and automobiles not only perform well but also stand out visually. The use of laminated glass also speaks to a commitment to quality and long-term performance. It withstands significant wear and tear over time, resisting issues like discoloration and delamination that can affect other glass types. For property owners and automotive enthusiasts who value longevity and reliability, this makes 13.52 laminated glass an investment worth making. Industry experts and manufacturers underscore the importance of choosing high-quality laminated glass from reputable suppliers. Ensuring compliance with international safety standards and verifying the manufacturer’s credentials builds trust and confirms the authenticity of the product. It's imperative to consult with professionals in the field to select the right specifications that cater to specific needs, be it for safety, acoustic properties, or energy efficiency. In conclusion, 13.52 laminated glass represents a confluence of safety, performance, and style. Its ability to protect, insulate, and enhance the aesthetics of a space makes it a preferred material in various applications. For those seeking a product that combines cutting-edge technology with real-world benefits, 13.52 laminated glass stands as a compelling choice. As consumers and industry professionals continue to prioritize safety and sustainability, the adoption of this innovative material is poised to grow, reinforcing its status as a leader in the glass industry.

Next:

Latest news

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS