1 月 . 15, 2025 09:54 Back to list

clear float glass price

Understanding the market dynamics for 10mm float glass can significantly aid in making informed purchasing decisions, especially when quality and cost-effectiveness are at stake. Known for its versatility and durability, 10mm float glass serves a wide array of applications, ranging from architectural glazing to intricate interior designs. The pricing factors are vast and nuanced, making it vital for anyone in the construction or design industry to grasp how these elements play together.

In markets where construction projects and renovations become seasonal peaks, it's common to see price hikes due to increased demand. For businesses or projects looking to source 10mm float glass, identifying these peak periods can lead to strategic purchasing decisions. Negotiating long-term contracts during off-peak times can lock in more favorable rates and ensure a steady supply chain unaffected by seasonal fluctuations. Furthermore, shipping and handling also contribute significantly to the overall cost of 10mm float glass. The product's bulk and fragility necessitate careful shipping strategies, often leading to additional costs. Collaborating with logistics providers specialized in handling fragile materials can optimize shipping expenses. Bulk purchases can sometimes lead to discounted rates, making it a sensible option for larger projects with substantial glass requirements. Considering environmental factors is another aspect that is gaining momentum. Increased emphasis on sustainability has led some manufacturers to adopt more eco-friendly technologies and processes, which may slightly raise prices. However, many organizations and governments provide incentives or tax benefits for using sustainable materials, which can mitigate additional costs—highlighting corporate responsibility and possibly achieving long-term financial gains. In conclusion, while numerous variables influence the price of 10mm float glass, understanding these dynamics allows for strategic decision-making. Engaging with reputable suppliers, considering geographical and seasonal factors, and prioritizing quality and sustainability not only ensure cost-effectiveness but also add value in terms of product performance and safety. Armed with this knowledge, industry professionals can navigate the complexities of the market with confidence, securing essential materials without compromising on standards.

In markets where construction projects and renovations become seasonal peaks, it's common to see price hikes due to increased demand. For businesses or projects looking to source 10mm float glass, identifying these peak periods can lead to strategic purchasing decisions. Negotiating long-term contracts during off-peak times can lock in more favorable rates and ensure a steady supply chain unaffected by seasonal fluctuations. Furthermore, shipping and handling also contribute significantly to the overall cost of 10mm float glass. The product's bulk and fragility necessitate careful shipping strategies, often leading to additional costs. Collaborating with logistics providers specialized in handling fragile materials can optimize shipping expenses. Bulk purchases can sometimes lead to discounted rates, making it a sensible option for larger projects with substantial glass requirements. Considering environmental factors is another aspect that is gaining momentum. Increased emphasis on sustainability has led some manufacturers to adopt more eco-friendly technologies and processes, which may slightly raise prices. However, many organizations and governments provide incentives or tax benefits for using sustainable materials, which can mitigate additional costs—highlighting corporate responsibility and possibly achieving long-term financial gains. In conclusion, while numerous variables influence the price of 10mm float glass, understanding these dynamics allows for strategic decision-making. Engaging with reputable suppliers, considering geographical and seasonal factors, and prioritizing quality and sustainability not only ensure cost-effectiveness but also add value in terms of product performance and safety. Armed with this knowledge, industry professionals can navigate the complexities of the market with confidence, securing essential materials without compromising on standards.

Latest news

-

Wired Glass: A Strong and Secure Glass Solution for Various Applications

NewsNov.04,2024

-

Tinted Glass: A Stylish and Functional Choice for Modern Homes

NewsNov.04,2024

-

The Elegance and Versatility of Silver Mirrors

NewsNov.04,2024

-

The Advantages of Copper Free Mirrors

NewsNov.04,2024

-

Tempered Glass: A Reliable Choice for Modern Applications

NewsNov.04,2024

-

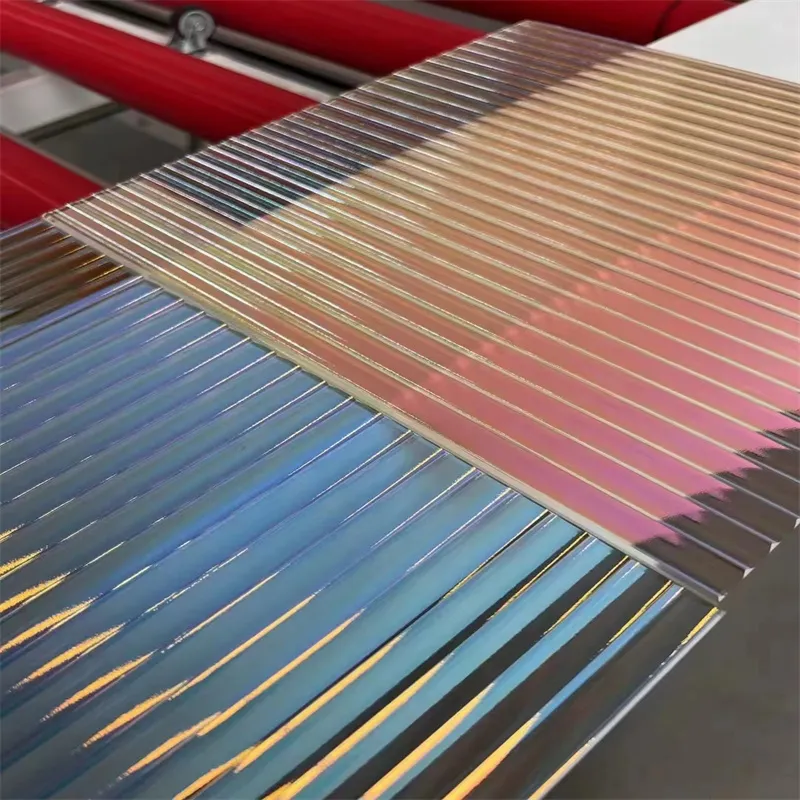

Pattern Glass: Stylish and Functional Glass for Modern Design

NewsNov.04,2024

Related PRODUCTS